/ EV Charging Made Quick & Convenient

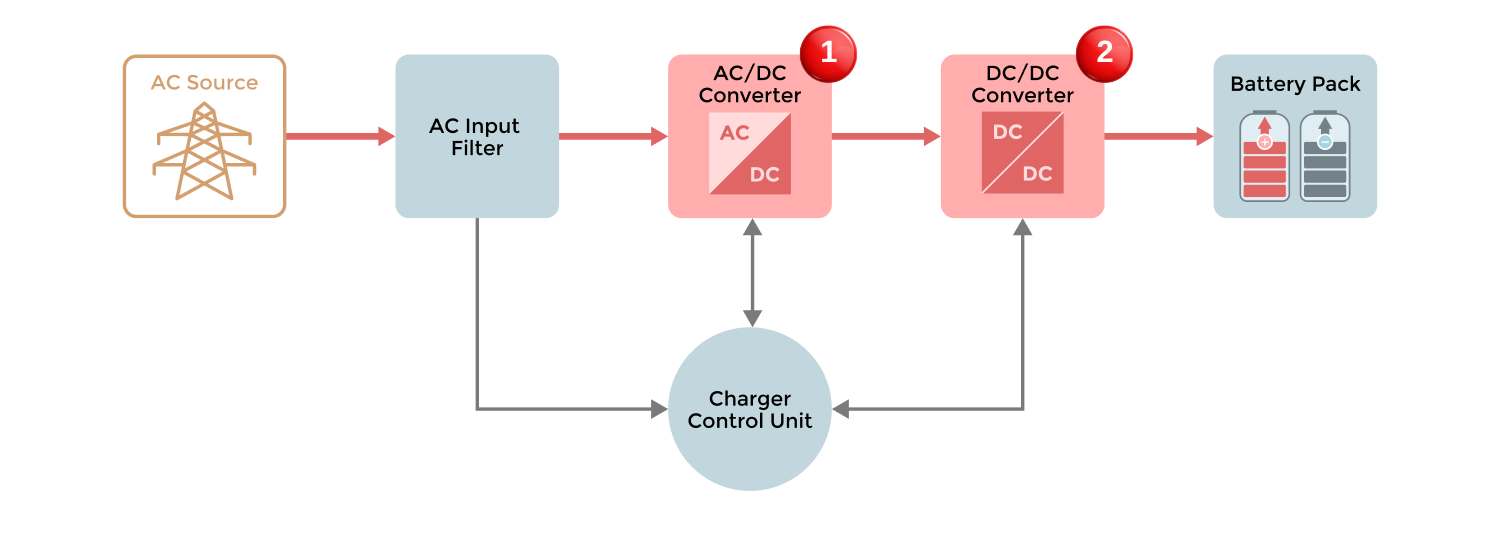

For some drivers accustomed to the in-and-out refueling of a gas station, the time investment for charging EVs was a deterrent in switching to more sustainable vehicles. That’s where DC fast charging comes in. Compared to other EV charging options with voltages from 120V to 400V, DC fast chargers reduce downtime from 6-8 hours to 20-30 minutes.These innovative systems bypass the vehicle’s on-board charger (OBC) and provide power to the battery. Converting the power to the appropriate levels for charging the EV is a two-step process:

First, the alternating current (AC) from the grid must be converted into a DC (direct current) link of approximately 800V with the help of a 3-phase full bridge power factor correction (PFC) rectifier.

Next, a sub-unit power converter reduces the incoming high-voltage DC link to the appropriate voltage for the vehicle’s battery, which is already DC power.

This DC-DC conversion can take place in two ways:

CLLC DC-DC Converter - the capacitor-inductor-inductor-capacitor (CLLC) DC-DC converter utilizes a symmetric resonant network for bidirectional power distribution. The converter is highly efficient since the LLC resonant tank has zero voltage switching capability.

Dual Active Drive (DAB) DC-DC Converter - this bidirectional DC-DC converter uses identical primary and secondary side full bridges, known as dual active bridges. A high-frequency intermediary transformer delivers galvanic isolation.

/ Application Considerations

When designing DC fast chargers and sub-unit power converters, engineers should consider the following:

- Charging speed - the charging speed should complement the size and capacity of the EV battery

- High-voltage capability - to minimize losses and improve efficiency, a high-voltage, low-current approach is recommended

- Safety - several strategies must be implemented to promote safety, from thermal management to ESD protection

- Efficiency - reducing energy and heat losses while providing the most power to the vehicle’s battery is essential

- Cost - upfront costs and ongoing expenses should be considered when designing fast-charging solutions

- Compatibility - the EV charging system must be compatible with the battery, the vehicle’s charging port sizes, and all applicable regulations

- Scalability - as the availability of fast EV chargers remains a barrier for some consumers, designing for multiple vehicle types and battery sizes is crucial

- Environment - the system should be designed to perform reliably amid extreme temperatures and other environmental conditions

- Industry standards - DC chargers must comply with applicable standards, which may include Combined Charging System (CSS) or CHAdeMO

/ DC Chargers Solutions